Description

ORALITE® 9900 Brilliant Grade Premium #020 Yellow

ORALITE® 9900 Brilliant Grade Premium is highly reflective, weatherproof, self-adhesive sheeting with excellent corrosion and

solvent resistance for the manufacture of durable permanent outdoor signing. The product complies with the requirements

described in the ASTM D4956 standard for Type XI retroreflective sheeting

Product Construction

ORALITE® 9900 Brilliant Grade Premium consists of sealed cells of air backed microprisms using total internal reflection. The

distinct shape of the sealing identifies the machine direction and the manufacturer of the sheeting (see drawing).

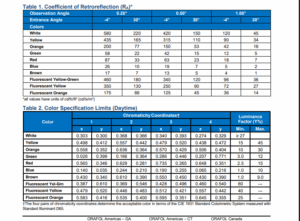

Reflectivity

ORALITE® 9900 Brilliant Grade Premium meets and/or exceeds the

minimum coefficient of retroreflection (RA) shown in Table 1 when

tested in accordance with ASTM E810, “Standard Test Method for

Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the

Coplanar Geometry”. ORALITE® 9900 Brilliant Grade Premium fully

meets and/or exceeds the requirements of ASTM D4956 for Type XI.

Daytime Color

ORALITE® 9900 Brilliant Grade Premium conforms to the daytime color

requirements in Table 2 when tested in accordance with ASTM D4956.

ORALITE® 9900 Brilliant Grade Premium is available in white, yellow,

orange, green, red, blue, brown, fluorescent yellow, fluorescent yellow green and fluorescent orange.

Nighttime Color

ORALITE® 9900 Brilliant Grade Premium conforms to the nighttime color requirements in Table 3 when tested in accordance with

ASTM D4956 and ASTM E811. The sheeting shall be measured using CIE illuminant A with an observation angle of 0.33° and an

entrance angle of +5°.

Adhesive

The adhesive is protected by a release liner which shall be removed by peeling, without soaking in water or other solvents. The

adhesive produces such a bond that a 1” (50 mm) strip shall support a 1 3/4 pound (0.79 kg) weight for 5 minutes without the strip

peeling for a distance of more than 2″ (50 mm) when applied to a smooth aluminum surface as specified in the ASTM D4956,

section 7.5 adhesion test.

Impact Resistance

Following application to a smooth surface aluminum rectangle, 0.040” x 3” x 6” [1.01mm x 75mm x 150mm], the specimen is

conditioned for 24 hours at 73° ± 3°F (23° ± 2°C) and 50% relative humidity, subject the sheeting to an impact of a 2 lb (0.91 kg)

weight with a 5/8” (16 mm) rounded tip dropped from a 10 in-lb (1.13 N-m) setting on a Gardner variable impact tester, IG-1120, as

per ASTM D4956, section S2.2.1. The sheeting shall show no cracking or delamination outside the actual area of impact.

Flexibility

The sheeting is conditioned for 24 hours at 72°F [23°C] and 50% relative humidity. The release liner is removed and the sheeting is

sufficiently flexible to show no cracking when bent in one second’s time around a 1/8-inch [3.2mm] diameter mandrel with the

adhesive contacting the mandrel.

Weatherability

ORALITE® 9900 Brilliant Grade Premium meets the requirements of ASTM D4956, Section 6.4. The material is weather resistant

and shows no appreciable cracking, scaling, pitting, blistering, edge lifting, curling, or more than 1/32” (0.8 mm) shrinkage or

expansion. Retroreflectivity measurements are conducted after outdoor weathering with an observation angle of 0.20º and entrance

angles of -4º and +30º.The minimum coefficient of retroreflection (RA) after weathering is 80% of the values specified in Table 1.

Solvent Resistance

ORALITE® 9900 Brilliant Grade Premium meets the requirements of LS-300C solvent resistance, section 3.6.7, when tested as

specified in Table VI, test method 4.4.6.

Specular Gloss

ORALITE® 9900 Brilliant Grade Premium shall have a specular gloss of not less than 40 when tested in accordance with ASTM

D523 at an angle of 85°.

Shrinkage

A 9 inch by 9 inch [229mm by 229mm] specimen of the sheeting with liner is conditioned a minimum of one hour at 72°F [23°C] and

50% relative humidity. The liner is then removed and the specimen is placed on a flat surface with the adhesive side up. Ten

minutes after the liner is removed and again after 24 hours, the specimen is measured to determine the amount of dimensional

change. The specimen will not shrink in any dimension more than 1/32 inch [0.8mm] in 10 minutes and 1/8 inch [3.2mm] in 24

hours.

Application Instructions

It is recommended that the application temperature to achieve best results is 65°F [18°C] or above.

Warranty

12-year limited warranty for White, Yellow, Green, Red, Blue and Brown.

10-year limited warranty for Fluorescent Yellow-Green and Fluorescent Yellow.

3-year limited warranty for Orange and Fluorescent Orange.

Contact your ORAFOL Americas Inc. representative for details.